Project sound insulation analysis

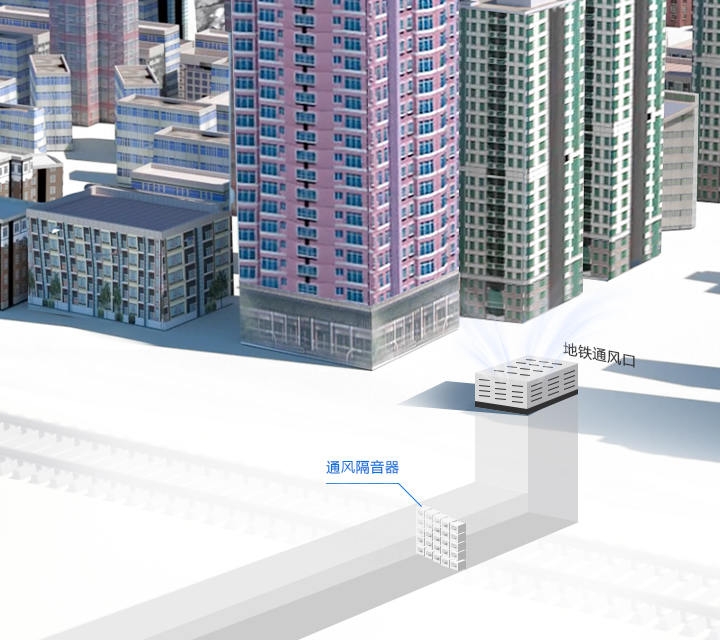

The air vents in the subway are constantly buzzing

The noise from subway air outlets is mostly low-frequency noise, and the sound is loud. Traditional sound insulation cotton technology has little effect on reducing low-frequency noise. Residents near the subway often suffer from the "buzzing" of the air outlets.

Adequate ventilation area needs to be ensured

The subway fresh air system itself is to ensure the fresh air demand in the subway station. On the premise of meeting the sound insulation, it has a sufficient ventilation ratio to fully meet the fresh air demand in the subway space.

Need to meet the installation space requirements of the air duct

The subway ventilation duct is fully enclosed, which greatly increases the difficulty of construction. The length of traditional sound insulation cotton material exceeds 3 meters, which greatly increases the difficulty and cost of installing noise reduction materials.

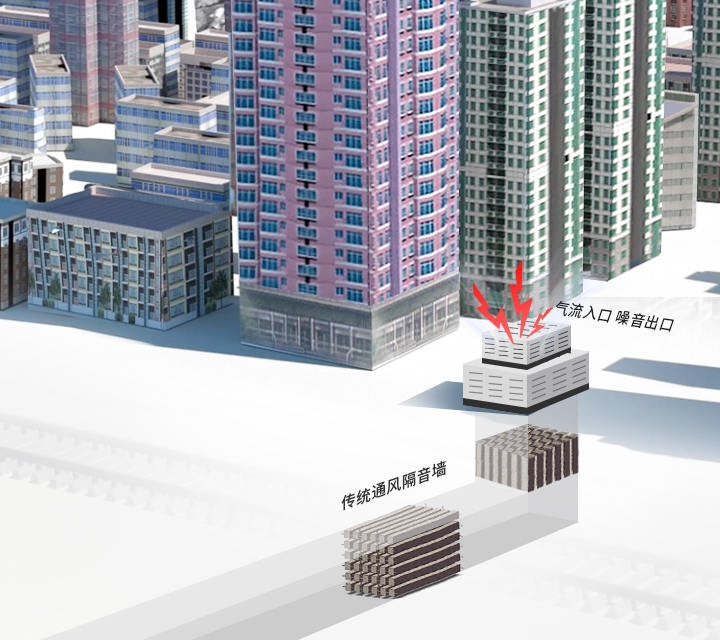

Traditional soundproof cotton sound insulation at subway entrance

Tranquility Acoustronics new generation metamaterial ventilation and sound insulation

Solutions

Full-band noise reduction spectrum design

Based on the noise frequency band characteristics of subway vents and the noise spectrum characteristics of different subway vents, Lingbo Yisheng designs the sound insulation spectrum and customizes Lingbo Yisheng sound insulation modules to achieve full-band noise reduction.

Largely expand the ventilation area

The ventilation area is as high as 50%, which effectively meets the sound insulation of the whole frequency band and fully ensures the proportion of ventilation area.

Significantly reduces installation thickness

Lingbo Yisheng adopts thin film resonance noise reduction technology, which greatly reduces the dependence on material thickness. Compared with the 3m installation thickness of traditional sound insulation cotton, Lingbo Yisheng's installation thickness is as low as 0.3m, which greatly reduces the installation difficulty.

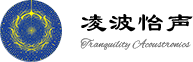

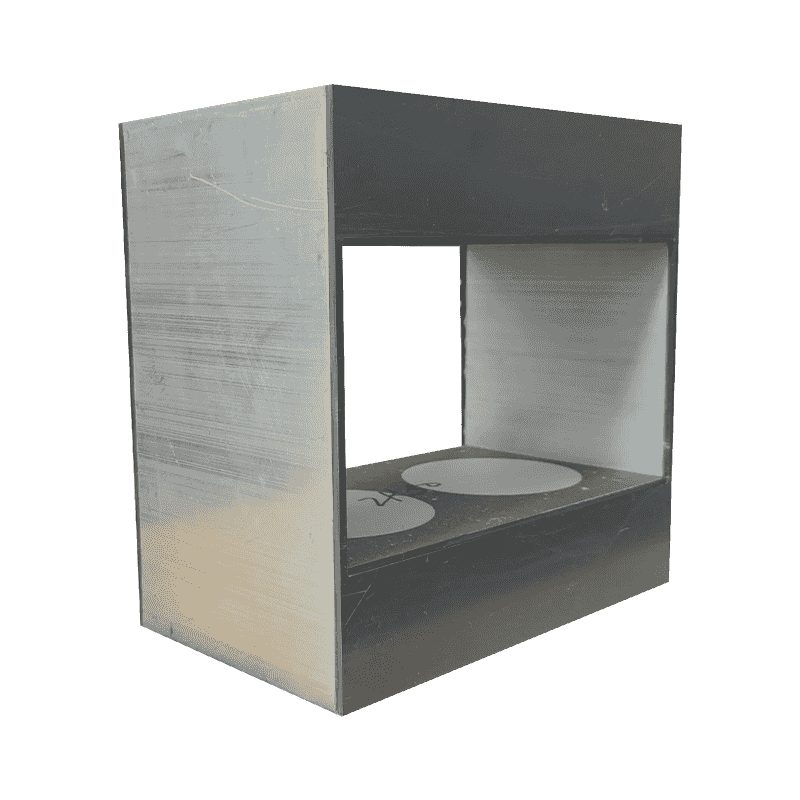

Optional ventilation sound isolator module

ULF module: length 200 mm, weight 38 kg per square meter

Noise reduction by 10-15 decibels below 150Hz

Universal module: length L=450 mm, weight per square meter 84 kg

Low-frequency noise reduction (150-500Hz) 12-15dB, mid-frequency noise reduction (500-1500Hz) 25-30dB, high-frequency noise reduction (1500-5000Hz) 20-25dB, dBA total noise reduction 22-27 decibels